The first stones tell a different story when water enters the plan. A French team led by Xavier Landreau proposes a hydraulic lift inside Djoser’s Step Pyramid, and the idea reframes labor, tools, and timing at once. The claim touches methods, not myths, because Pyramids rise with engineering choices, and water can shape force, speed, and accuracy without leaving easy traces.

A New Lens on Ancient Engineering

For a century, long ramps defined the mainstream model. Mudbrick causeways and teams of haulers seemed enough, while blocks moved inch by inch. Landreau’s group, writing in PLOS ONE, shifts the load inside the monument. Vertical shafts, careful grading, and planned cavities, they argue, could host fluid power, so stones climb without steep external structures, yet with tight control and repeatable steps.

“Volcano construction” names the core idea. Buoyancy does the heavy lift as water pressure rises within confined shafts. Blocks float, then settle on prepared ledges, because small level changes translate into steady movement. The Pyramids gain precision from this control, so joints line up, and errors shrink as each lift follows the last, while survey markers track height from the heart outward.

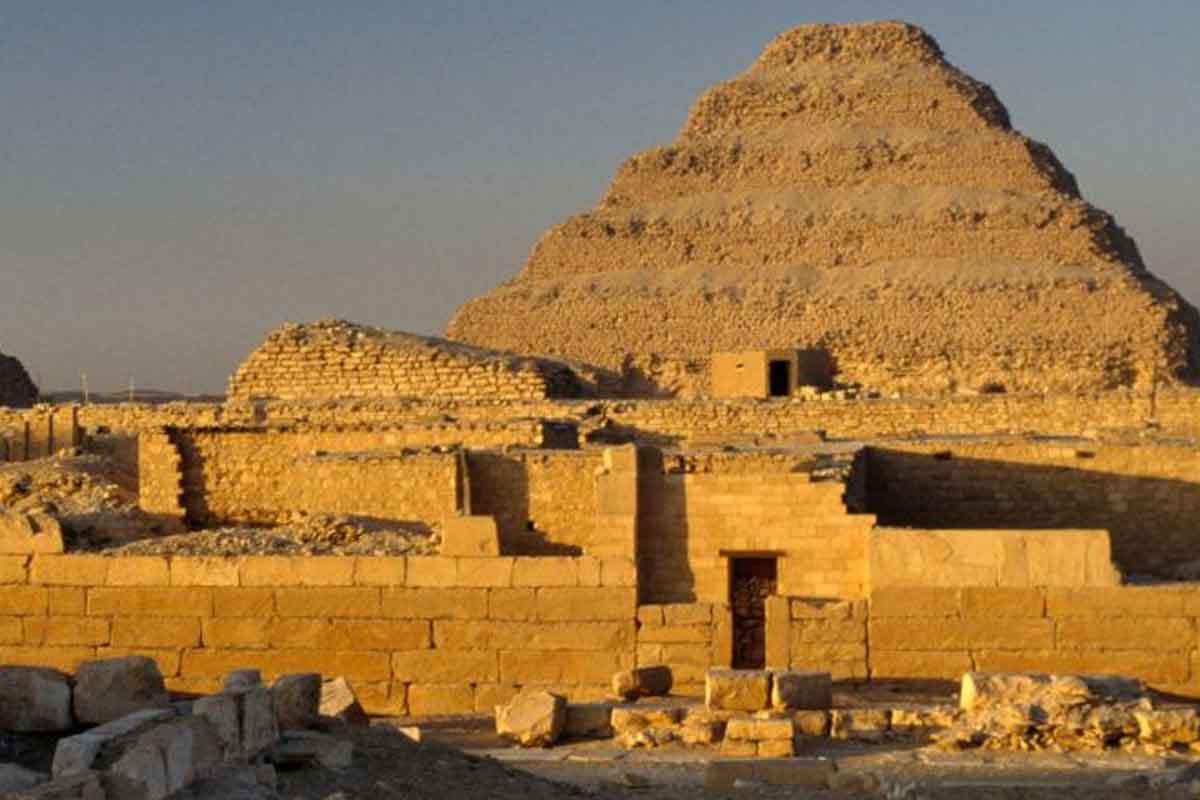

The Step Pyramid of Djoser anchors the claim. Built around 2680 BC at Saqqara, it predates Giza but sets patterns. The team maps topography and hydrology, then checks satellite imagery for channels, basins, and rock cuts. They study nearby wadis, which carry floodwater after storms, and they outline routes that could feed a controlled, repeatable system inside the monument itself.

Hydraulic Clues Inside the Pyramids’ First Monument

Gisr el-Mudir sits west of the pyramid, huge and enigmatic. Rather than a ceremonial wall, the team reads it as a check dam. It could trap sediment and regulate flow. As spates arrive from Abusir Wadi, the basin would hold water and release it in measured pulses, so internal shafts receive pressure in steps, not in chaos, while operators time each stage.

The Dry Moat that encircles the complex adds more function. Once labeled symbolic, it may filter water before use. Deep rock-cut compartments act like baffles; silt settles, and debris stays put. Clean input matters because grit erodes channels and valves, so filtration protects surfaces, and steady clarity keeps the lift predictable. When pressure is planned, accuracy becomes routine.

Together, dam and moat create a system, not a backdrop. Stored flow, filtered feed, and internal shafts form linked parts. Operators control heads, volumes, and timing with simple gates and slopes. Ramps still exist for access, yet the heavy raising happens inside. The structure becomes both machine and monument, as walls guide water and water guides stone, step after step.

Practical Stakes, Gains, and Caution for Field Work

Egypt’s builders knew water. Irrigation taught them gradients, and transport by barge taught balance. Moving blocks on the Nile proves buoyancy solves weight, while canals show how current behaves. The hydraulic lift simply applies those lessons in closed shafts. Inside the Pyramids, tight spaces amplify small differences, so little drops in level still deliver reliable lift.

Precision follows from control. The team links internal tunnels and shafts to exact alignments. When lifts repeat under measured pressure, joints close cleanly, and courses stay level. Survey points track each rise, and templates lock angles. Stone tolerances grow tighter, so interiors read like instruments. The effect feels modern because planned forces produce consistent results, then the finish shows it.

The proposal needs checks on the ground. Rock faces may retain wear patterns from controlled flow. Sediment layers could record staged releases. Tool marks around gates or slots would strengthen the case. Field teams can probe joints, scan filled cavities, and map micro-channels. Hydraulic models can test volumes, while dye traces reveal paths, so evidence and simulation meet.

Water, Stone, and Pyramids : A Technical Reading

Data anchors claims. PLOS ONE sets the study for review, and dates fix the frame: Djoser’s project around 2680 BC at Saqqara. Satellite scenes map basins, while surveys chart the Dry Moat’s compartments. The Gisr el-Mudir enclosure, massive and plain, fits a dam’s logic because sediment traps need breadth, and controlled spillways thrive where wide walls tame sudden flow.

Comparisons matter because devices scale. A barge floats tons when volume displaces water; a shaft can do the same on a vertical plan. Smaller head, narrow walls, and sealed doors turn depth into lift. Pressure grows with column height, so a modest charge moves heavy blocks. Operators pace cycles, then lock stones as levels fall, and the next course begins.

If confirmed, the timeline shifts. Water-lifting tools known from later eras would no longer mark the start. Millennia open between Djoser and standard histories of pumps. That gap invites re-reads of quarry marks, causeways, and ramps. Old finds gain new roles, and missing parts become expected. Machines hide well when walls double as their housings.

What a water-powered vision could change, and what to check next

Water can be both gift and tool, and that dual role fits Egypt. If the hydraulic lift explains Djoser’s Step Pyramid, then known skills—irrigation, barges, careful surveying—combine into unseen machines. The case remains open, so careful digs and measured tests matter. Evidence will rule, and Pyramids will keep their edge while the debate stays alive.